> Blogs > 7 Production Process of Colored High-Transmittance Glass: From Raw Material to Radiance

7 Production Process of Colored High-Transmittance Glass: From Raw Material to Radiance

Core keyword: colored high-transmittance glass

Colored High-Transmittance Glass is transforming the boundaries of material design—bringing vibrant colors without compromising on optical clarity. Whether used in luxury architecture, designer lighting, or technical optical panels, this glass type requires a specialized production process that balances aesthetics with performance. So what’s the exact manufacturing process for colored high-transmittance glass? Let’s examine it in detail.

The Manufacturing Workflow of Colored High-Transmittance Glass

1. Raw Material Selection

The journey begins with ultra-clear silica sand, typically over 99.5% SiO₂, blended with fluxes like soda ash and limestone. What sets Colored High-Transmittance Glass apart is the rigorous selection of materials to minimize impurities that would otherwise hinder light transmission. For coloring, minute quantities of metal oxides are added.

-Cobalt oxide produces brilliant blue.

-Chromium oxide yields rich greens

-Selenium or cadmium sulfide imparts warm reds and yellows

2. Batch Mixing and Color Calibration

The chosen raw materials and colorants are blended under regulated conditions. Uniform distribution is crucial; uneven mixing can lead to color bands or cloudy patches. Modern facilities use automated dosing systems to maintain batch-to-batch consistency in both hue and transparency.

3. Melting and Refining

The batch mixture is then introduced into a high-temperature furnace (1,500–1,600°C). Here, materials fully melt, interact, and undergo refining:

-Impurities are eliminated

-Colorants dissolve and integrate with the base glass.

-Fining agents (e.g., sodium sulfate) remove micro-bubbles.

This step is central to achieving the high optical purity characteristic of colored high-transmittance glass.

4. Forming Techniques

Depending on the end product, the molten glass can be formed by:

1. Float method for flat glass

2. Blow or press molding for decorative items or lighting components

To preserve transmission, the forming surface must be smooth, defect-free, and dimensionally consistent.

5. Annealing Process

After the glass is formed, it must undergo gradual cooling in a lehr oven to eliminate internal stresses. Failing to perform this step or expediting the cooling process may lead to deformation or unexpected cracking. Through controlled annealing, the glass achieves both optical clarity and mechanical durability, ensuring its structural stability for practical use.

6. Surface Treatments (Optional)

Colored high-transmittance glass may undergo:

1. AR (anti-reflective) coatings for optical applications

2. UV-resistant layers for architectural installations

3. Acid polishing or sandblasting for enhanced texture and clarity

7. Final Inspection and Quality Assurance

Each batch is tested for:

-Light transmittance, typically in the visible spectrum

-Color uniformity, verified by spectrophotometers

-Surface defects, bubbles, and strain marks

Only glass that satisfies both aesthetic and technical standards is authorized for packaging.

Conclusion

The production of Colored High-Transmittance Glass is a fusion of precision engineering and artistic vision. From meticulous raw material selection to advanced forming and annealing, every step contributes to its remarkable clarity and vivid coloration. It’s more than just decorative—it’s functional brilliance.

Looking for custom Colored High-Transmittance Glass for your next architectural project?

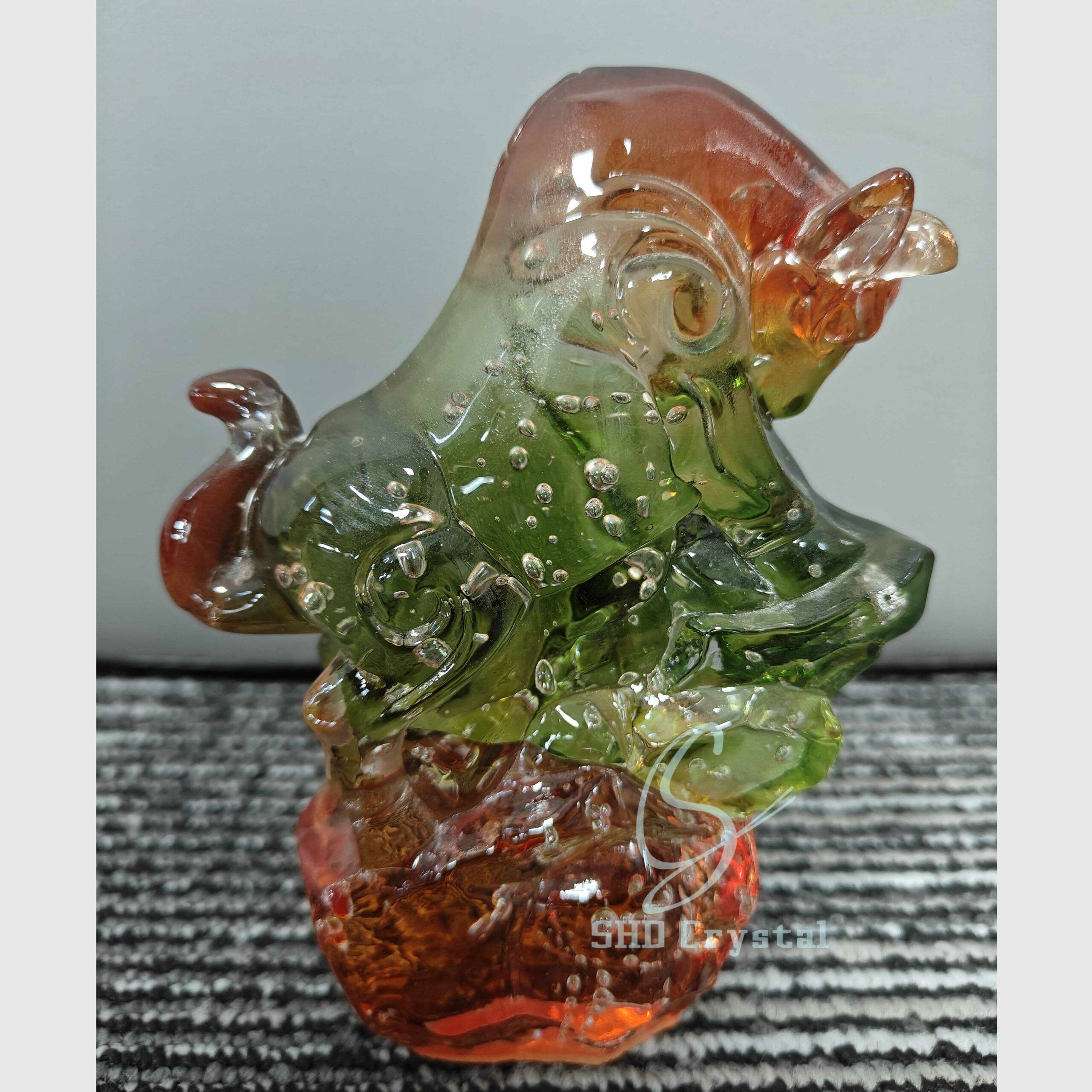

At SHD Crystal, we specialize in the design and manufacturing of high-performance colored crystal glass tailored for architectural applications. From gradient curtain walls to bespoke lighting elements, our team collaborates closely with architects, designers, and developers to deliver precision-crafted, high-transparency glass solutions that meet both aesthetic and structural demands.

Get in touch with SHD Crystal to explore how our Colored High-Transmittance Glass can bring brilliance and clarity to your vision.

- : info@shdcrystal.com

- : +86-755-2335 8353

- : No. 68 Shasong Road, Shajing Street, Bao'an District, Shenzhen, Guangdong Province

Follow us