> Blogs > Kiln Forming: The Art of Shaping Crystal Glass with Fire and Precision

Kiln Forming: The Art of Shaping Crystal Glass with Fire and Precision

Core keyword: kiln forming

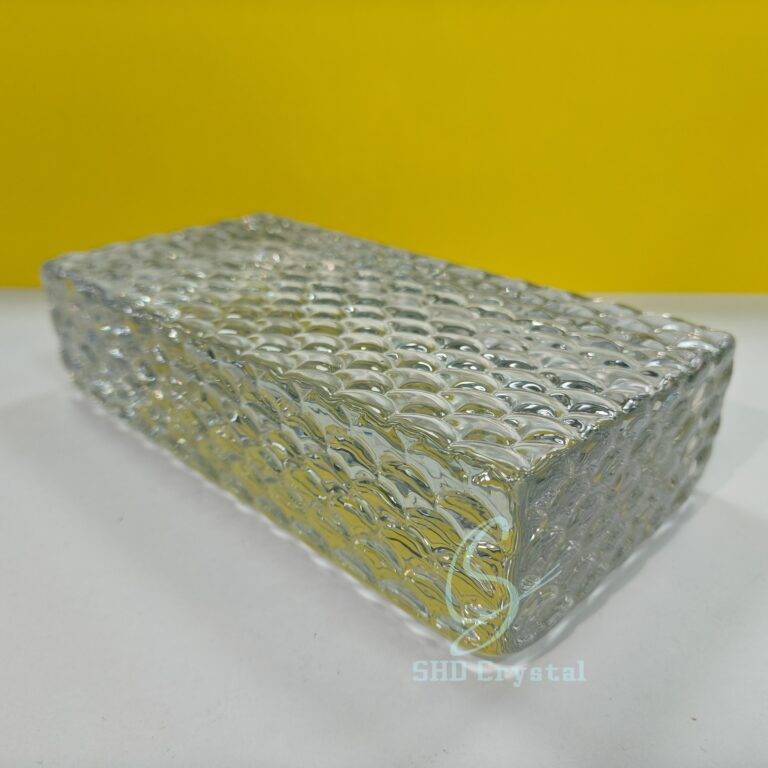

Kiln forming, also known as kiln-fused glass, is an advanced technique where layers of crystal glass are heated in a temperature-controlled kiln until they melt, fuse, or slump into molds. Unlike traditional glassblowing, this method allows unparalleled precision in creating intricate textures, layered designs, and custom geometries.

Key Characteristics of Kiln Forming

1. Temperature Mastery

Kiln forming demands precise ramp/soak/cool cycles (typically 600°C–900°C), enabling control over transparency, opacity, and surface texture.

2. Design Versatility

Artists stack, cut, or layer glass sheets to achieve:

- 3D sculptures

- Dimensional lighting components

- Seamless color blends

3. Strength & Clarity

Slow annealing in the kiln eliminates internal stresses, resulting in crystal-clear, durable pieces resistant to thermal shock.

Applications: Where Kiln Forming Shines

✅ Luxury Lighting

Chandelier components (prisms, shades) with light-diffusing patterns.

✅ Architectural Elements

Backlit wall panels, fused glass partitions.

✅ Art & Décor

Sculptures, tabletops, and bespoke installations.

Kiln Forming Market Trends & Customer Perspectives

The global kiln-formed glass market is experiencing steady growth, valued at $2.8 billion in 2024 and projected to reach $4.1 billion by 2030 (CAGR 6.5%). This surge is driven by:

Luxury Interior Demand: High-end hotels and residences increasingly commission custom kiln-formed lighting (e.g., chandeliers, backlit walls) for unique ambiance.

Architectural Innovation: 60% of commercial projects now specify kiln-fused glass for durability and light-diffusing properties (2023 AIA Report).

Sustainability Shift: Clients favor kiln forming over traditional methods due to near-zero material waste (vs. 20% loss in glassblowing).

What Customers Say About Kiln-Formed Products

1. Designers Praise Precision

“Working with kiln-formed crystal lets us achieve geometries impossible with blown glass, like our 120cm fractal pendant for the Dubai Opera.”

2. Architects Value Performance

“The anti-glare textured panels from SHD Crystal reduced our project’s artificial lighting needs by 30%.”

3. End-Users Love the “Living Light” Effect

Over 92% of positive reviews on Houzz mention kiln-formed glass’s dynamic refraction: “At different hours, the pendant casts ever-changing rainbows, like showing a sunset.”

Why This Matters for Buyers

Kiln forming’s market momentum ensures:

✅ Investment-Worthy Designs (resale values 15-20% higher than mass-produced lighting)

✅ Future-Proof Compliance (meets evolving EU/US safety standards for public spaces)

Conclusion

Kiln forming is more than a technique—it’s a dialogue between material science and artistic ambition. From the kiln’s precise 800°C embrace to the final polished edge, every step unlocks crystal glass’s potential to elevate spaces with light and texture.

Looking for custom kiln-formed Glass Pieces for your next project?

At SHD Crystal, we harness kiln forming to transform your visionary designs into tangible artistry. Whether you’re a lighting designer seeking bespoke crystal components or an architect envisioning fused glass masterpieces, SHD Crystal delivers kiln-forming excellence.