> Blogs > Engineering Light: The Intricate Glass Block Manufacturing Process

Engineering Light: The Intricate Glass Block Manufacturing Process

Core keyword: glass block manufacturing process

In an age where sustainability meets aesthetic ambition, the glass block manufacturing process has transformed these modular units from industrial utility into architectural artistry. Yet their true magic lies in a century-old process refined through modern engineering. At SHD Crystal, we dissect this alchemy of sand and science.

Understanding the Glass Block Manufacturing Process: From Raw Clarity to Engineered Brilliance

To truly appreciate the versatility and beauty of modern glass blocks, one must look beyond their aesthetic finish and delve into the technical artistry behind their creation. The glass block manufacturing process is a carefully choreographed sequence where material science, thermal dynamics, and industrial precision converge—each stage playing a crucial role in defining optical clarity, structural integrity, and design adaptability.

Phase 1: Raw Material Alchemy—The Foundation of Clarity

Glass blocks begin as a meticulously calibrated blend:

- Silica Sand (70%): Derived from high-purity quartz with iron content below 0.015% to avoid greenish discoloration.

- Soda Ash (18%): Lowers melting temperature from 1,700°C to 1,500°C, reducing energy use by 30%.

- Limestone (10%): Enhances chemical durability against weathering.

- Recycled Cullet (25-30%): Crushed waste glass cuts CO₂ emissions by 5% per ton.

- Critical Control: Grain size distribution (100-500μm) ensures homogeneous melting.

Phase 2: Melting & Refining – Thermal Engineering at Its Core

Inside regenerative furnaces (30m x 10m):

1. Batch materials enter at 1,200°C, reaching 1,550°C in the melting zone.

2. Molten glass held 24+ hours for fine refining:

-Boron nitride stirrers homogenize viscosity.

-Temperature gradients ≤2°C prevent cord defects

3. Electrostatic precipitators capture 99.8% of particulate emissions.

Phase 3: Forming – Precision in Motion

Method A: Press-and-Blow (80% of blocks)

1. Shearing: IR sensors cut 1.2kg “gobs” (±5g tolerance)

2. Pre-Molding: Tungsten-carbide molds shape half-blocks at 1,050°C

3. Blowing: 8-bar compressed air expands glass to final dimensions

4. Demolding: Robotic arms transfer blocks to the annealing lehr

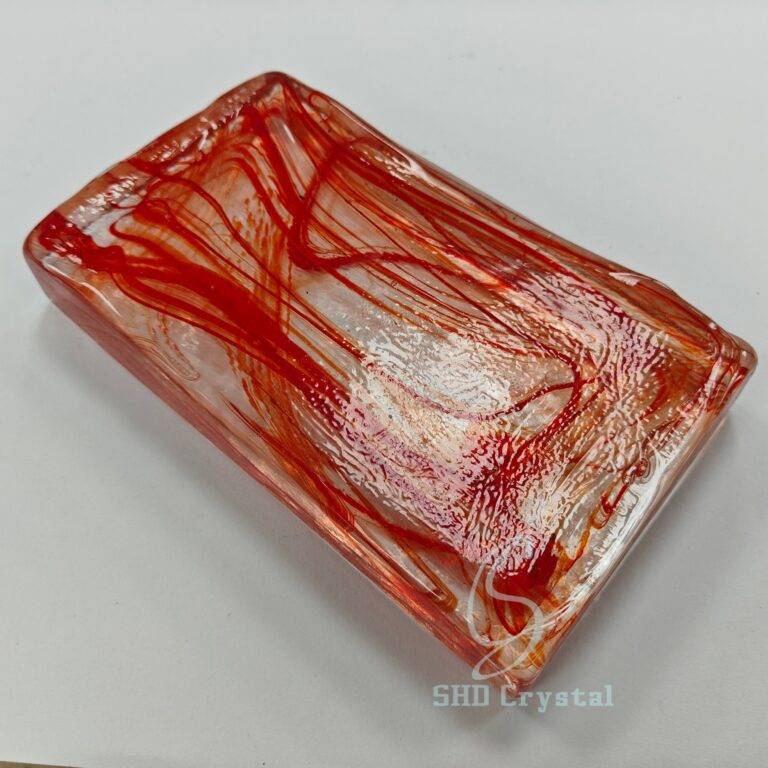

Method B: Centrifugal Casting (Textured/Specialty Blocks)

1. Molten glass poured into spinning graphite molds (200-500 RPM)

2. Creates wave, prism, or diamond patterns

Phase 4: Annealing – The Silent Art of Stress Relief

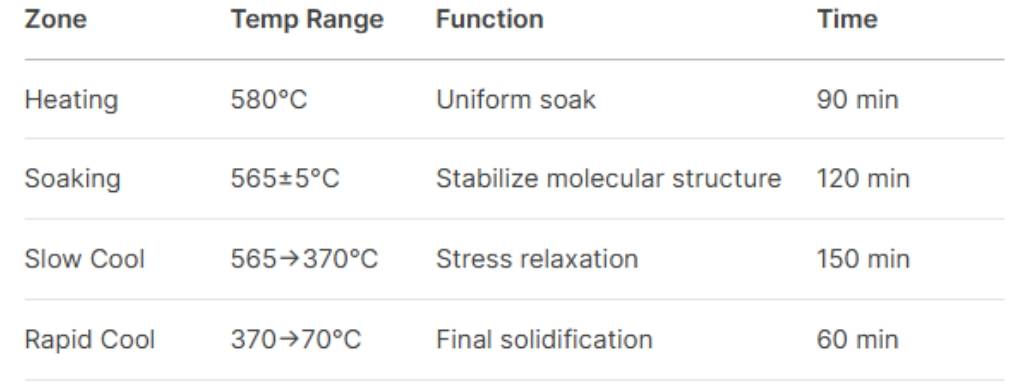

Blocks traverse a 60-meter-long oven in 6 critical stages:

Phase 5: Sealing & Inspection – Where Precision Meets Perfection

1. Infrared Fusion:

Halves aligned and heated to 800°C

IR emitters fuse seams in 90 seconds

2. Vacuum Testing:

Blocks submerged, 0.5-bar vacuum applied

Bubble streams indicate leaks (reject rate <0.1%)

3. Laser Scanning:

Dimensional tolerance: ±0.3mm

Defect detection: ≥0.15mm inclusions

Conclusion: The Future Cast in Glass

The glass block manufacturing process stands as a testament to industrial poetry, where geology, thermodynamics, and robotics converge to shape light itself. Glass blocks embody the marriage of industrial precision and natural light – a testament to how human ingenuity harnesses the earth’s elements to shape luminous spaces.

SHD Crystal: Beyond Standard Blocks – Your Vision, Perfected

While the glass block manufacturing process sets the foundation, SHD Crystal transforms this legacy through revolutionary solution tiers.

“SHD’s chromatic blocks didn’t just meet our spectral design needs—their R&D team engineered a new glass composite to achieve our impossible amber gradient.”

– Fiona Zhang, Message from the manager of an interior design company in Shanghai

Explore SHD’s Glass Block Innovation Portfolio → Where tradition meets tomorrow’s architecture.