> Blogs > How to Make Glass Tableware: 6 Proven Techniques from Blowing to Casting

How to Make Glass Tableware: 6 Proven Techniques from Blowing to Casting

Core keyword: how to make glass tableware

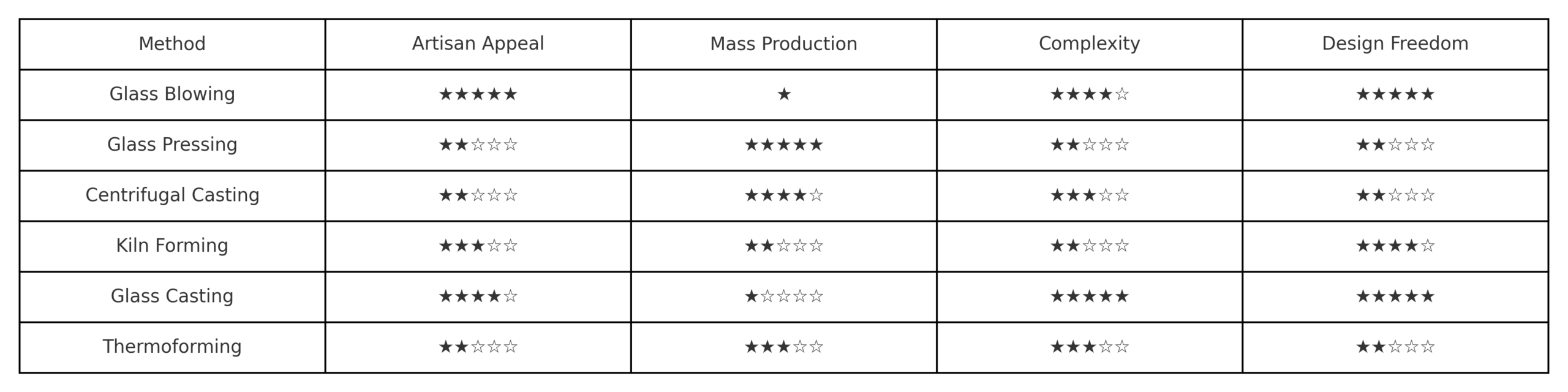

Glass tableware combines functionality with artistry. If you’re curious about how to make glass tableware, there are two dominant traditional methods you should know: glassblowing and glass pressing. Each offers a unique aesthetic and texture, and both continue to shape the world of artisan and mass-produced tableware today.

Techniques That Show How to Make Glass Tableware That Balances Art and Practicality

Glassblowing is the oldest and most artistic method. It begins with molten glass, gathered on the end of a blowpipe. The artisan inflates it by blowing, shaping it with hand tools, gravity, and motion. The process allows for fluid curves and organic designs. Blown glass tableware—plates, bowls, and cups—often carries air bubbles and slight asymmetries that reflect its handmade charm.

“When you blow a bowl by hand,” says Master Liu, a craftsman with 30 years of experience, “you can feel the soul of the fire inside it. That’s what machines can never replicate.”

On the other hand, glass pressing, or mold pressing, is a more efficient method, especially for mass production. It involves dropping molten glass into a mold and pressing it with a plunger. This process is ideal for creating uniform pieces with detailed surface patterns, such as embossed designs or logos. Pressed glass is thicker and sturdier, often found in hotels, restaurants, or affordable home collections.

For those exploring how to make glass tableware beyond the traditional, there are several other common techniques used in the glass industry, each with its strengths and limitations:

1. Centrifugal Casting

Also known as spin casting, this method spins molten glass inside a mold, using centrifugal force to form smooth, even shapes. It’s commonly used for round, symmetrical pieces like trays and shallow bowls. The process results in uniform geometry while significantly reducing the chance of air bubbles forming within the glass. However, it requires specialized machinery and is best suited for high-volume production of simple shapes.

- Use rate: Moderate

- Difficulty: Medium

- Finish: Clean lines, less texture variation

- Advantage: Good for large sizes with minimal defects

2. Kiln Forming (Slumping/Fusing)

In kiln forming, flat sheets of glass are slowly heated in a kiln until they soften and either fuse (fusing) or slump into molds (slumping). This process is widely used for making glass platters, cheeseboards, and decorative dishes. While the method allows creative design through layering and coloring, it’s limited in dimensional complexity.

- Use rate: High in studio glassmaking

- Difficulty: Low to medium

- Finish: Often decorative, artistic

- Advantage: Great for pattern work and custom designs

3. Glass Casting

This method involves pouring molten glass into a refractory mold where it cools slowly. Casting allows for thick, sculptural pieces—ideal for statement bowls or centerpiece plates. It requires long cooling times (annealing) and careful mold preparation, making it more suitable for artistic, low-volume work.

- Use rate: Niche

- Difficulty: High

- Finish: Heavyweight, tactile

- Advantage: High design freedom, but labor-intensive

4. Thermoforming / Hot Bending

Though more common in architectural applications, thermoforming also sees occasional use in tableware design. Glass sheets are heated and bent over metal molds to create serving trays, glass covers, or minimalist dishes. It works best for modern, sleek esthetics but lacks the depth and complexity of blown or cast pieces.

- Use rate: Limited

- Difficulty: Medium

- Finish: Smooth, geometric

- Advantage: Efficient for flat and angular shapes

Which Method is Best for You?

Each technique contributes differently to the world of glass tableware. Whether you seek industrial efficiency or handcrafted individuality, knowing how to make glass tableware helps you navigate the possibilities with informed choices.