> Blogs > Shipping of Fragile Glass Hookahs: Engineering, Protection, and Zero-Damage Delivery

Shipping of Fragile Glass Hookahs: Engineering, Protection, and Zero-Damage Delivery

Core keywords: shipping of fragile glass hookahs, protective packaging design, in-transit damage reduction

In the luxury glassware industry, shipping of fragile glass hookahs determines final quality as much as production itself. Even flawless craftsmanship can fail if transport systems allow shocks, vibration, or stacking pressure to create microcracks or scuffs. SHD Crystal integrates shipping of fragile glass hookahs directly into its manufacturing workflow—engineering packaging, validating routes, and auditing stability to ensure safe arrival every time.

Shipping of Fragile Glass Hookahs: A Precision Engineering Process

Treating shipping of fragile glass hookahs as a structured engineering discipline—not a last-minute step—prevents most downstream breakage. Effective execution links product geometry, protective packaging design, carrier capabilities, and real-world handling data. Every dimension—from the base rim to the decorative collar—is mapped to specific buffer zones inside customized packaging. This transforms logistics from a risk exposure into a measurable quality control ecosystem.

Test-Driven Validation for Real Shipping Conditions

SHD Crystal replicates realistic transport hazards through standardized laboratory testing:

-Drop tests (76–92 cm) simulate courier handling

-Random vibration testing simulates road + sea exposure

-Compression + tilt tests evaluate pallet stability

Packaging is approved only when it passes all criteria tied directly to in-transit damage reduction. This lets every shipment operate under an evidence-based SOP rather than assumptions.

Standardized Packing and Traceability

Operators follow documented sequences: base → cradle → collar → liner → close → seal. Each batch includes photographic archiving and signed verification. This procedural clarity ensures shipping of fragile glass hookahs becomes quantifiable and repeatable—not dependent on individual packing habits. Standardization is key to scalable in-transit damage reduction.

Risk Mapping: Where Glass Meets Gravity

Each shipping lane has its own stress pattern: vibration frequency, transfer count, humidity variation, and temperature spikes. Before shipment, SHD Crystal analyzes these variables to generate tolerance models. Ocean routes with 30–40 days of micro-vibration exposure influence cradle density, cardboard compression rating, and protective packaging design specifications. This analytical approach ensures that shipping for fragile glass hookahs remains consistent across global distribution networks.

Packaging as Mechanical Engineering

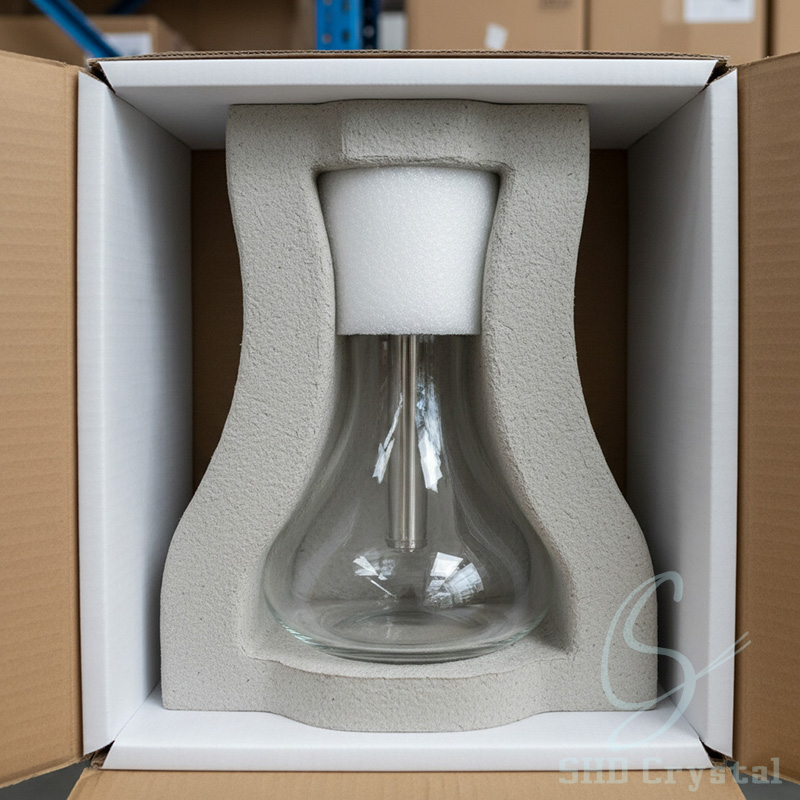

Every layer in a protective packaging design serves a deliberate mechanical function within the shipping system. Soft collars shield the necks of delicate pieces, molded pulp or EPE cradles support the bases, and liners prevent abrasion on coated surfaces. High-strength outer cartons provide compression resistance to protect against stacking pressure. Each of these engineered components is chosen to use drop-test data, vibration modeling, and material fatigue analysis—far beyond improvised bubble-wrap solutions. The result is shipping of fragile glass hookahs built on scientific protection rather than unpredictable carrier handling.

Palletization and Structural Integrity

At the macro level, protective packaging design aligns with pallet geometry. No carton overhang, uniform load distribution, reinforced edges, and full deck support collectively maintain vertical compression strength. Proper strapping and stretch wrap ensure alignment during impacts or forklifts—direct contributors to in-transit damage reduction across SKUs.

Environmental Control and Carrier Qualification

Moisture, heat, and vibration vary by trade lane. Desiccants, anti-slip mats, and thermal indicators are added selectively when supported by data—not guesswork. Carriers are vetted for fragile-cargo programs, tracking reliability, and scan-chain transparency. Factory-to-lane synchronization advances shipping of fragile glass hookahs by removing unknowns in transport behavior.

Factory Integration: From Forming to Freight

Because SHD Crystal controls glass melting, shaping, inspection, and final packaging in-house, every protective measure is calibrated to real product geometry and material physics. This vertical ecosystem strengthens both protective packaging design and in-transit damage reduction, resulting in deliveries that match showroom-quality expectations.

Partner With SHD Crystal for Zero-Damage Shipping

Collaborate with SHD Crystal to engineer shipping of fragile glass hookahs through certified packaging systems, vibration analysis, pallet audits, and data-driven validation. Our expertise in protective packaging design and proven in-transit damage reduction methods ensures your products arrive with flawless aesthetics and integrity.

Conclusion

In premium glassware, true quality doesn’t end at the furnace—it survives the journey. When executed scientifically, shipping of fragile glass hookahs becomes a brand advantage, transforming fragility into a guarantee of reliability and craftsmanship.