Table of Contents

ToggleOEM Crystal Vase Manufacturing Process

Cooperation Process:

Inquiry & Communication → NDA Execution → Requirement Confirmation → Design & Quotation → Order Agreement → Production & Delivery → Service Advantages & Customer Assurance

This cooperation process outlines our standard workflow for OEM crystal vase manufacturing projects.

I. Inquiry & Communication

Professional sales engineers from SHD Crystal provide full-process support throughout the initial communication stage, responding to customer inquiries and technical questions related to OEM crystal glass vase manufacturing, including but not limited to 24% lead crystal glass vases, lead-free crystal glass vases, decorative vases, and other customized crystal glass vase products in various styles and specifications.

II. NDA Execution

To safeguard customer product designs and business information, SHD Crystal provides Non-Disclosure Agreement (NDA) execution to ensure confidentiality and data security.

III. Requirement Confirmation

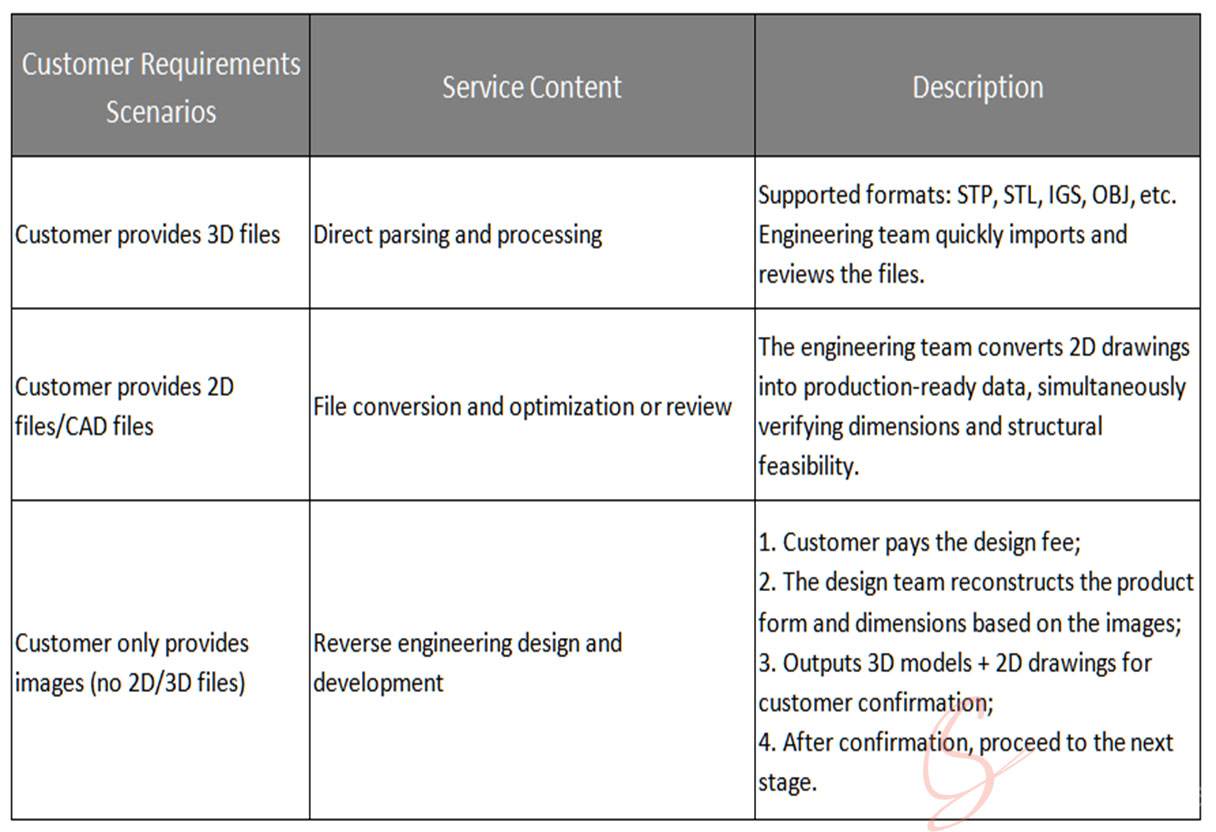

Key Sales Action: Engineering Review → Regardless of the documents/materials provided by the customer, the engineering team will conduct a process feasibility review, provide structural optimization suggestions, and estimate costs to ensure the design plan is compatible with actual production requirements for custom crystal vase manufacturing.

IV. Design & Quotation

- Pricing Basis: The engineering team conducts a detailed cost breakdown based on customer requirements (material selection, production process, post-processing requirements, and order quantity) to generate a detailed quotation.

- Customer Interaction: A professional sales team provides full support throughout the process, answering pricing questions and adjusting plan details until the customer confirms the quotation.

V. Order Agreement Execution

- Order Confirmation: After the customer confirms the quotation, a formal cooperation agreement is signed, clearly defining key terms such as product specifications, delivery schedule, and payment methods.

- Payment Methods: We support flexible payment methods, including TT (Telegraphic Transfer) and PayPal, to accommodate the payment habits of customers in different regions.

- Payment Milestones: After signing the agreement, the customer pays a pre-agreed percentage of the total amount as a down payment (the specific percentage is as agreed in the agreement). Production-related preparations (mold making/material procurement) will begin after the down payment is received.

VI. Production & Delivery

This stage covers tooling preparation, material procurement, core manufacturing processes, secondary processing, quality control, packaging, and logistics, supporting stable and consistent crystal glass vase production across different order requirements.

1) Production Preparation: Mold Making / Moldless Process Selection

a. Mold Making: For machine-pressed and some blown products, dedicated molds are made based on the confirmed 3D model to ensure consistency in mass production (high-quality mold steel is used for the molds to extend their lifespan).

b. Moldless Hand Shaping: For highly customized, small-batch, or uniquely shaped products, a hand-shaping process is used, eliminating the need for molds, shortening the production cycle, and reducing costs for small-batch customization.

c. Material Preparation: Corresponding materials (24% lead crystal glass / colored glass / lead-free glass) are purchased according to the order agreement. All materials undergo environmental and quality testing and comply with relevant international standards.

2) Core Production Stage: Comprehensive Process Coverage, Ensuring Quality and Efficiency

a. Production Process Selection (matched as needed):

b. Machine Pressing Process: Suitable for mass production and products with regular shapes. Advantages include high efficiency, high dimensional accuracy, and controllable costs.

c. Blowing Process: Divided into mechanical blowing and manual blowing, suitable for products with smooth curves and dynamic shapes, highlighting the transparent texture of crystal glass.

d. Hand Shaping: Purely handcrafted, suitable for artistic and highly personalized custom products. Each piece combines practicality and aesthetic appeal.

e. Production Control: Multiple inspection points are set up during the production process, and technicians monitor product molding quality in real time and adjust process parameters promptly.

3) Post-Processing: Diversified Processes to Enhance Product Value

a. Optional Post-Processing Processes (customized as needed):

✅ Polishing/Grinding: Improves the surface finish of the product, removes burrs, and enhances the transparency of the crystal.

✅ Baking Paint: Single-color/multi-color baking paint, supports custom color numbers, wear-resistant and non-fading.

✅ Electroplating: Metal-textured plating (gold, silver, rose gold, etc.), enhancing the high-end feel.

✅ Sandblasting: Local/overall sandblasting to create a frosted texture and add design layers.

✅ Engraving: Mechanical engraving/manual engraving, supports custom patterns (floral, geometric, logo, etc.).

✅ Gold/Silver/Enamel Painting: Precisely outlines details, showcasing a luxurious texture, with bright and long-lasting enamel colors.

b. Process Features: All post-processing steps are performed by professional technicians, strictly adhering to customer design requirements to ensure uniform and stable process results.

4) QC Full Inspection: Strict quality control to eliminate defects. Full inspection process:

a. Raw Material Inspection: Verification of material composition, appearance, and dimensions to ensure compliance with order requirements.

b. Semi-finished Product Inspection: Sampling inspection of molded and post-processed products during the production process to promptly identify and correct problems.

c. Finished Product Full Inspection: Every finished product undergoes multi-dimensional testing, including appearance (no bubbles, no scratches, no cracks), dimensions (precise matching to drawings), process effect (post-processing quality), and function (stability).

d. Inspection Standards: Adhering to international crystal glass product quality standards; all non-conforming products are reworked or scrapped to ensure 100% qualified products are delivered.

5) Packaging Stage: Safety Protection + Customized Adaptation

a. Safety Packaging (Standard Configuration): Three-layer protection using pearl cotton + bubble wrap + hard cardboard box, with built-in shock-absorbing buffer structure to effectively prevent collisions and wear during transportation and ensure product integrity.

b. Customer Customized Packaging (Optional): Customized packaging design according to customer needs (printing logo, brand information, patterns), providing gift box packaging, color box packaging, etc., supporting personalized selection of packaging materials, specifications, and processes.

c. Packaging Inspection: After packaging, simulated transportation tests (drop and vibration tests) are conducted to ensure the effectiveness of packaging protection.

6) Product Delivery: Flexible Transportation, On-time Delivery

a. Transportation Methods (Select as needed):

- Sea Freight: Suitable for large-volume orders, cost-effective, supports full container/less than container load (LCL) shipping.

- Air Freight: Suitable for urgent orders, fast transportation speed, covering major airports worldwide.

- Express Delivery: Suitable for small batches of samples or urgent items, door-to-door service, guaranteed timeliness (DHL, FedEx, UPS, etc. cooperative express companies).

- Land Transportation: Suitable for surrounding areas or inland customers, flexible transportation, stable timeliness.

b. Delivery Instructions:

- Logistics Selection: Supports customer-designated logistics service providers, or we can recommend high-quality logistics partners.

- Logistics Tracking: After shipment, a tracking number will be provided, and the sales team will track the transportation status in real time and provide timely feedback to the customer.

VII. Service Advantages & Customer Assurance

Service Advantages

- Flexible Design: Supports multi-type file integration + reverse engineering of images, meeting the design needs of different customers.

- Comprehensive Craftsmanship: Covers machine pressing, blowing, and manual shaping, adaptable to different batch sizes and customized shapes.

- Controllable Quality: Full-process quality inspection from materials to finished products, ensuring product consistency and high quality.

- Efficient Service: Professional sales and engineering teams provide full support, quickly responding to customer needs and shortening project cycles.

- Diverse Customization: Materials, processes, post-processing, packaging, and transportation can all be customized, providing a one-stop solution.

Customer Guarantees

- Quality Guarantee: Delivered products meet the standards agreed upon in the contract. In case of quality problems, returns, exchanges, or rework are supported.

- Timeliness Guarantee: Production and delivery are completed strictly according to the delivery cycle agreed upon in the contract, avoiding delays.

- Privacy Guarantee: Customer design plans, product information, and other business secrets are kept strictly confidential and will not be disclosed to third parties.

- After-Sales Guarantee: Technical support is provided after product delivery to answer questions related to use and maintenance.

These service capabilities enable custom crystal glass vase manufacturing with flexible order quantities, controlled quality standards, and reliable delivery schedules.