From concept design to scalable production, our team supports OEM glass project development and high-precision crystal product customization across luxury, décor, lighting, and functional glass fields.

Where Custom Crystal Manufacturing Turns Ideas into Production-Ready Products

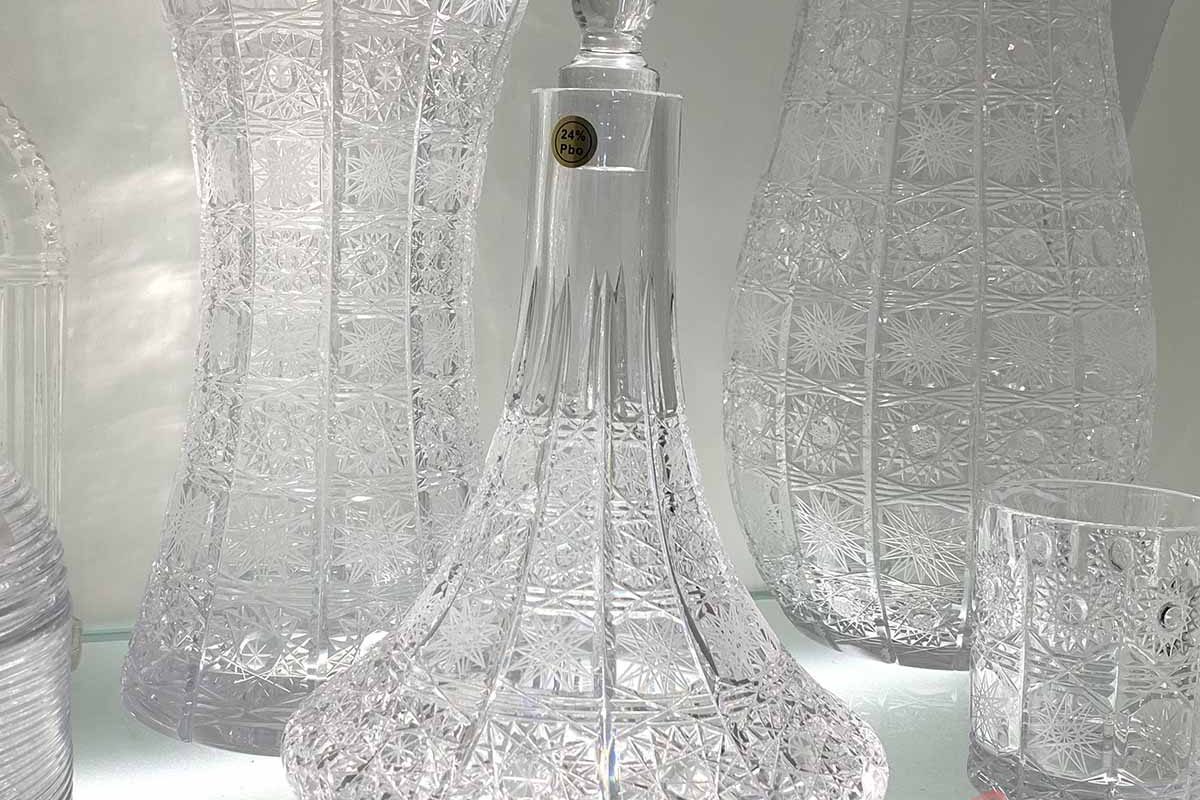

This page showcases active directions in our custom crystal manufacturing work. Rather than displaying standard catalog items, these projects represent real OEM glass project development cases where structure, process feasibility, and visual design are engineered together.

Each project reflects how crystal product customization moves from concept evaluation to stable production models, ensuring both artistic value and manufacturing reliability.

▪ Project Type 01

Custom Glass Lampshade Project

Developed for lighting brands, this project involved shape stability during high-temperature forming, edge treatment for safe installation, and optical diffusion control. It demonstrates how custom crystal manufacturing extends beyond décor into functional light engineering.

▪ Project Type 02

Hand-Carved Crystal Hookah Base Structural Development

This crystal product customization project focused on large-volume hollow structure stability, including balanced wall thickness, internal cavity symmetry, and base reinforcement—validated through forming trials to ensure repeatable OEM production feasibility.

Every Project Follows a Structured Manufacturing Workflow

All new projects are managed through our standard custom crystal manufacturing system, including feasibility review, mold planning or free-forming selection, sample validation, and controlled mass production. This structured approach ensures that every crystal product customization project moves smoothly from development to delivery.